factory

If you are a factory of police equipment, you need to find a factory to help you do co processing. Parz industry is your best choice.

You can choose various cooperation methods: OEM, ODM, joint-stock factories, etc:

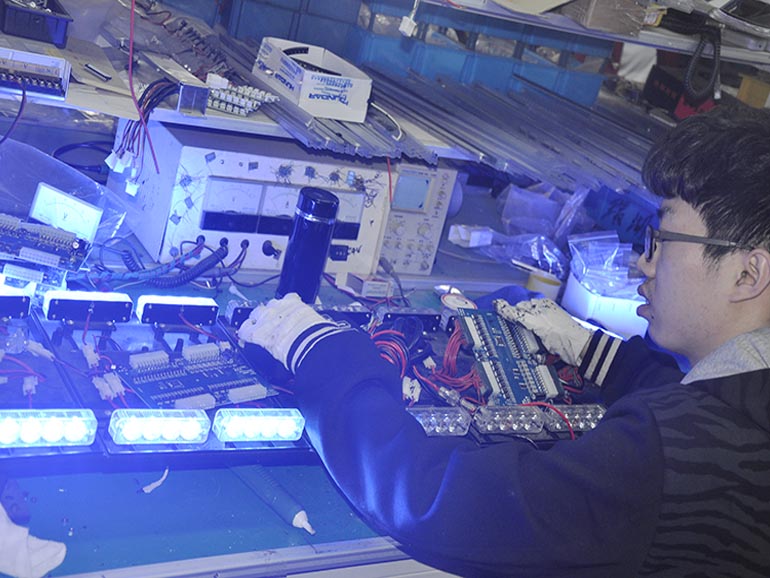

Perfect factory production management mechanism

We have more than 8000 square meters of standard plant, more than 150 manufacturing workers, more than 20 years of professional factory manufacturing management experience, 5 mature production lines, more than 15 professional quality inspection teams, 10 professional senior software and hardware engineers, and the company's perfect organizational structure and production management structure can ensure that your order can be delivered with quality and quantity guaranteed as soon as possible..

Facilities of the factory

1. The production, inspection, packaging, warehouse and other areas of

the factory are all equipped with high-power LED lights; The loading

area of the shipment is also equipped with a 50 square canopy;

2. The production area of the factory adheres to the "5S" system: timely

sorting, timely rectification, timely cleaning, timely cleaning, and

on-site management with adequate training;

3. The inspection area of the workshop is divided into qualified product

area and unqualified product area, and professional quality inspection

engineers make quality inspection records;

4. Equipped with various testing equipment and instruments: such as

luminous flux tester

Machine calibration and maintenance

1. Keep the machine clean and in good operating condition;

2. Each machine has engineer maintenance and repair records;

3. Important tools are placed on special shelves

Incoming material control

1. Use the warehouse management software in the ERP system to

control and record the incoming and outgoing of materials;

2. According to the order, the procurement plan is listed in the

ERP system to standardize the material procurement;

3. The warehouse is equipped with qualified product area and

unqualified product area to isolate unqualified materials;

4. Different materials are classified and placed in different

warehouses and areas;

Production control

1. The factory pre production meeting requires the quality

supervisor and workshop supervisor to hold a pre production

meeting together to review and improve important quality

problems and safety audits;

2. QC personnel shall keep detailed records of the

comparison between the first article sample and the standard

confirmation sample of large goods;

3. 100% quality testing of all products and keeping

records;

4. There is a special packaging area of more than 300 square

meters and a special inspection waiting area of more than

400 square meters;

5. Operation instructions are posted in the production,

inspection and packaging areas;

6. The company's sales department will track and record the

shipment to ensure on-time delivery;